What risks can arise during storage on a construction site?

- Being struck/crushed by a load/slipping of the load during handling;

- Cuts/abrasions/punctures of the body part by sharp parts of the load, during breakage, or slipping of the load;

- Development of musculoskeletal disorders, so-called MSDs – disorders of the back, neck, shoulders, and upper and lower limbs. See Risk factors / 5.6 Manual handling of loads.

- Burns from splashing, spilling, or dumping of a dangerous chemical substance or mixture;

- Slipping/spraining of the foot/collision with an obstacle during handling of loads;

- Burying of a person during storage of loose materials.

The following happened: occupational injury of a foreign worker during storage on a construction site with fatal consequences

While another company's employee was loading a steel frame, a row of approximately 6 similar frames tipped over. This assembly pinned the injured employee from Ukraine against the conveyor frame, which had been used here as a retaining element in case of tipping of said frames. The affected person created a temporary workplace from the conveyor frame, where he was standing inside and welding at the time of the accident. The injuries were fatal.

“Ten commandments” of site storage safety:

- Ensure safe supply and retrieval of material. Store the material according to the conditions specified by the manufacturer, preferably in a position in which it will be incorporated into the structure.

- Storage areas must be flat, drained and reinforced. Beware of the dimensions and load-bearing capacity of the storage areas (load-bearing capacity of the floor/ceiling – these must be loaded evenly) including roads – they must correspond to the dimensions and weight of the stored material and the machines used.

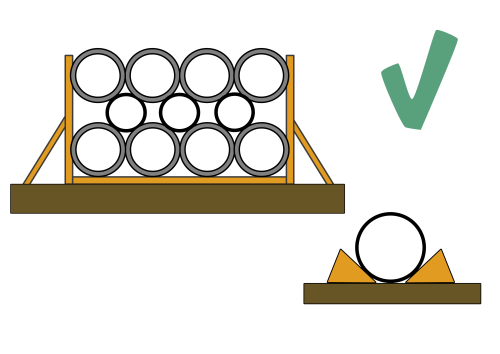

- Store materials in such a way that their stability is ensured throughout the storage period and they are not damaged. Use supports, stoppers, props, racks, wedges, or ties to secure all elements, parts, or assemblies that would otherwise be unstable and could overturn, collapse, shift, or roll.

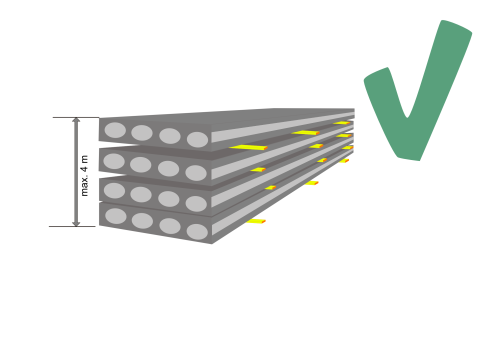

- Elements that closely contact each other during storage and are not equipped for safe handling (e.g., eyes, hooks, or handles) should always be separated by spacers. Do not use logs or layered spacers formed by two or more elements loosely placed on top of each other.

- Supporting or stabilizing structures shall allow the storage, removal or replenishment of elements and components in accordance with the accompanying documentation and without risk of damage.

- Places designated for tying, detaching, and handling material must be safely accessible. Attaching and detaching elements/parts/assemblies must be carried out from the ground or from safe floors. From a ladder only according to the established technological procedure.

- Cans and other round objects may be manually stored up to a height of 2 m, provided their stability is ensured. Secure pipes, logs and similarly shaped objects from spreading out. Obrázek

- Beware of creating overhangs when removing loose materials! When manually storing and retrieving, loose materials may be piled up to a height of no more than 2 m. If it is necessary to retrieve them manually, or by mechanical shovel from piles taller than 2 meters, adjust the retrieval site so that overhangs are not created and the height of the wall does not exceed 1.5 m. Obrázek

- Unauthorized natural persons are prohibited from entering a loose material landfill with bottom retrieval. If you secure the retrieval, do not linger in the danger zone of the retrieval site.

- Store loose materials in bags manually up to a height of no more than 1.5 m. In mechanized storage, if on pallets, up to a height of no more than 3 m. If the edges of the piles are not secured, for example, by supports or walls, the bags must be stored at a safe angle and bound so that they cannot slide. Obrázek

- Regularly shaped elements and parts during mechanized storage and retrieval are stored up to a height of 4 m, unless the manufacturer specifies otherwise. Pay attention to the load-bearing capacity of the base and ensure safe handling! Obrázek

- Store liquid material in closed containers so that the filling/emptying hole is at the top. Secure stored barrels and similar containers horizontally against rolling. Secure open tanks to prevent people from falling into them.

- Store hazardous chemical substances and chemical mixtures in containers labeled with the type and method of storage specified by the manufacturer, and mark in accordance with the requirements of specific legal regulations. Store chemicals and mixtures with respect to their properties and mutual reactivity. Prevent the possibility of confusion and harmful effects of stored substances! Do not under any circumstances pour chemicals into drinking bottles! Obrázek

More detailed storage safety requirements can be found here:

Annex No. 3 I to Government Regulation No. 591/2006 Coll., on more specific minimum requirements for occupational safety and health on construction sites

Annex (point 10) to Government Regulation No. 101/2005 Coll., on more detailed requirements for workplaces and work environment